Non-slip surfaces

Avoid liability risks and slipping hazards

They are afraid,

that someone slips and injures themselves?

As a store owner, building owner or person responsible in the public sector, you must ensure that your customers and visitors can safely enter your store or building as part of your duty of care. Unfortunately, this is not always successful and a slippery floor is the cause of numerous accidents.

According to the German Social Accident Insurance, the number of tripping, slipping and falling accidents in 2020 amounted to over

150.000

* German Social Accident Insurance, Work Accident Report.

Are you succeeding in fulfilling your duty of care and ensuring safety?

With the patented haid-tec process, slip resistance classes of R9-R11 can be achieved.

The patented haid-tec micro-blasting process

to increase slip resistance

The haid-tec process is a purely mechanical micro-blasting process.

Here, recesses (micropores) are created in the surface to be treated, e.g. natural stone, porcelain stoneware, etc., using special sandblasting and high pressure.

Safe in commercial

and barefoot area

With the haid-tec process you achieve:

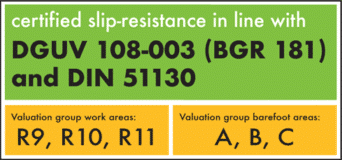

Slip resistance in accordance with DGUV Rule 108-003 (formerly BG Rule 181/DIN 51130) for the commercial sector in slip resistance classes R9-R11.

Slip resistance in accordance with DGUV Information 207-006 (formerly BGI_GUV-I 8527/DIN51097) for wet barefoot areas, e.g. swimming pool, spa, etc..

Safety and shine

are not mutually exclusive

The haid-tec micro-blasting process makes your floor shine – because with our process, safety and shine are not mutually exclusive.

We are able to process tiles & porcelain stoneware, natural stone, natural stone, glass, artificial stone, glazed and unglazed ceramics as well as shower trays and bathtubs.

Further processing steps at the factory – such as impregnation or color intensification – make natural stone in particular less susceptible to dirt and stains.

It is also possible to enhance the tonality, texture and color intensity of the material and to process large formats of 2.15 x 3.00 meters.

R9-R11

Safe floors

Certified slip resistance R9-R11 in commercial areas and in barefoot areas class A, B, C.

Impressive look

The original, aesthetic appearance of the floor does not change.

Large formats

Our systems can also process unsized panels in formats of up to 2.15 x 3.00 meters.

Versatile in use

Particularly suitable for coverings with mineral materials such as granite, marble, artificial stone, porcelain stoneware, glass, metals and plastics.

Microbeam process vs. other technologies

Laser technology

In contrast to laser technology, the indentations are scattered and applied to the surface without any recognizable direction. This means that no grid or raster is recognizable. The result is an almost natural, non-distracting pattern.

Acid and chemistry

In contrast to the use of acids and chemicals, the haid-tec process is absolutely reliable and also certified for higher slip resistance classes. Also environmentally friendly and compatible for humans and animals.

Slip mats

In contrast to slip mats, the haid-tec process does not pose any tripping hazards and therefore does not increase the safety risk.

haid-tec geprüfte Oberflächentechnik GmbH

Tested and certified

The haid-tec cleaning concepts are certified by recognized and accredited testing bodies:

IFA Institute for Occupational Safety and Health of the German Social Accident Insurance. The IFA is a research and testing institute of the German Social Accident Insurance Institutions for the industrial sector (BG)

TÜV SÜD is a technical testing organization that has set itself the task of protecting people, property and the environment from technical risks.

Säurefliesnervereinigung e.V. in Großburgwedel. Renowned testing and consulting institute for wall and floor coverings.

…

5 simple steps

1

Which standards must be observed? What risks can be minimized by taking appropriate measures? How can aesthetics, economy and sustainability be reconciled? Our experts provide up-to-date and individual advice.

2

Depending on the type of use, different materials and forms of processing can be considered. A reliably plannable compromise between aesthetics and safety must be achieved. Individually produced samples back up this decision. If a project-specific certificate is required, certification is initiated.

3

After reviewing the samples and consulting with all decision-makers, they are approved and the order is placed. Sample texts can be supplied in advance for tenders.

4

Factory processing is carried out at the Rottenacker plant after a specific date has been agreed. The delivered material is processed according to the specified slip resistance class and prepared for delivery on time.

5

The material arrives at the construction site punctually on the agreed date. It is already fully finished, non-slip in accordance with the relevant specifications and impregnated if required. This means it can be installed immediately. No further surface treatment is required on the construction site.

A selection of our references

Request now

Non-binding initial consultation

Send us your contact details and request your free and non-binding initial consultation today!

FAQ

We have summarized the most common questions for you in our FAQs.

If you cannot find an answer here, please do not hesitate to contact us.

The patented haid-tec process was developed to make porcelain stoneware and natural stone surfaces non-slip and less susceptible to dirt. The micropores introduced into the surface by the process, which lead to increased slip resistance and slip resistance, are protected by patent.

Within a few years, haid-tec was able to establish itself throughout the industry and become the innovation leader.

A small selection:

- In the industrial sector, several thousand square meters of steps and floor coverings made of granite and porcelain stoneware were processed for the market-leading construction machinery manufacturer Liebherr;

- in the retail sector, several tens of thousands of square meters of porcelain stoneware for the Müller drugstore chain; and several hundred thousand square meters of non-slip porcelain stoneware flooring for a market-leading retail company.

The systems are designed for oversized panels in formats of up to 2.15×3.00 meters.

Increases the slip resistance of polished and matt floor and stair coverings, especially those made of mineral materials such as granite, marble, artificial stone, porcelain stoneware and ceramics. The aesthetic appearance is largely retained.

The haid-tec® process as a mechanical process for achieving a defined slip resistance achieves slip resistance classes R9, R10, R11 for commercial areas and classes A, B, C for barefoot areas.

As early as possible. In other words, at an early planning stage. Costs can then be saved because the delivery date for the finished floors can already be planned. The worst possible time, however, is when slippery material has already been laid. Then there are only two alternatives: either I tear out the floor covering again to reinstall a newly finished one. Alternatively, the surface is processed directly on site, which incurs high costs and delivers an uncertain result. Because that would not be a certified surface treatment.

Installation companies in particular have the advantage that they can be supplied with finished and already impregnated surfaces. This means that no reworking is required on the construction site to make the floor resistant to water and oil. For the regular care of the floors, we offer care products tailored to the special requirements. As in other areas of natural stone, the same applies here: Do not experiment with the wrong cleaning and care products! However, if you follow the care instructions, you will have an easy-to-maintain, presentable floor. Even in highly frequented shopping arcades.

First of all, the obligation: We can offer surface treatment certified in accordance with DGUV Rule 108-003 (formerly BG Rule 181/DIN 51130) for the commercial sector or DGUV Information 207-006 (formerly BGI_GUV-I 8527/DIN51097) for wet barefoot areas. This means security for our customers. Because if an accident does occur due to slipping, it can be proven beyond doubt that planners, architects and, for example, store owners have fulfilled their duty of care.

Slip resistance is always a compromise between safety and aesthetics. Of course, natural stone can be etched with acid to make it safer. But in our opinion, this sometimes leads to unsightly results. We also don’t like the monotonous matrix structures that result from laser processing. We have therefore optimized our process so that it preserves the natural aesthetics of the stone as much as possible. After all, a prestigious floor made of natural stone should also be visually convincing and effective.

We also process the panels in the factory. The finished natural stone is therefore delivered to the construction site on time and without slipping, eliminating the need for an additional work step on the construction site. The fact that we can process raw panels in all available sizes would be a further advantage for planners working on exclusive projects.

Right from the start and even before the decision on the material used was made. Depending on the type of material, a higher slip resistance can affect the appearance of the stone to a greater or lesser extent. We therefore always recommend a sample finish so that the result can be assessed before installation.

With conventional methods, the finished floor is processed. The result can sometimes be a nasty surprise and lead to disputes between the client and the publisher. We used to treat soils with acid ourselves and are well aware of the pitfalls of this process. When carried out on site, we do not consider this technique to be reliable in terms of results or liability in the event of accidents. And this means that the parties involved have an unnecessary risk in the project. We can even show laymen the optical changes and varying degrees of etching with the naked eye. This makes it all the more annoying for an entrepreneur when the customer points out these differences. And it is even more annoying if the installed floor is not uniformly slip-resistant over the entire surface afterwards.